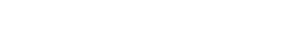

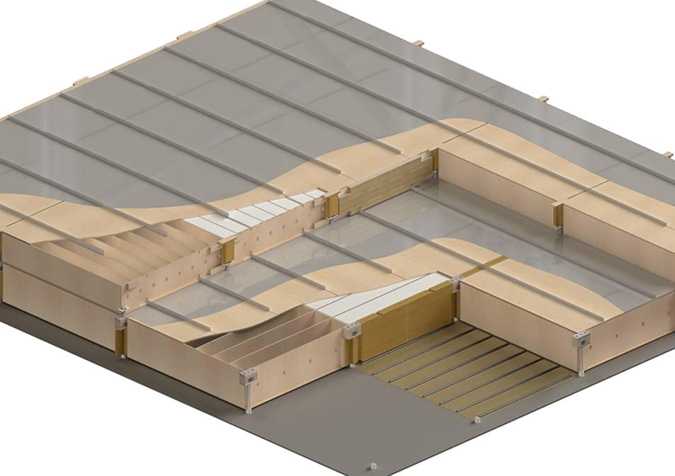

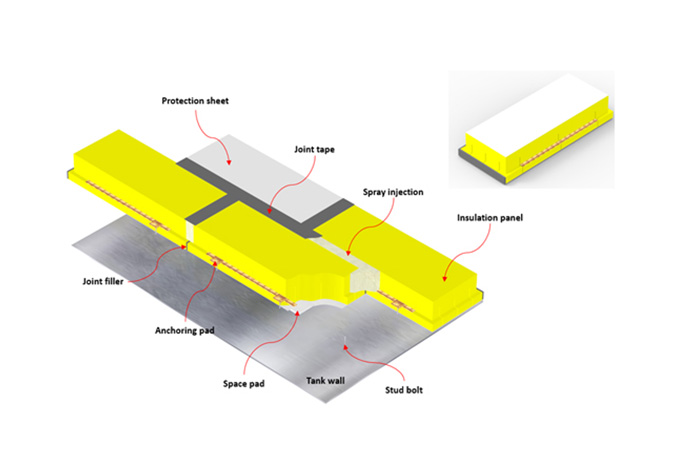

Insulation System

For over 20 years, with LNG cargo holds and LNG terminals,

our company has been recognized as the world’s best technology.

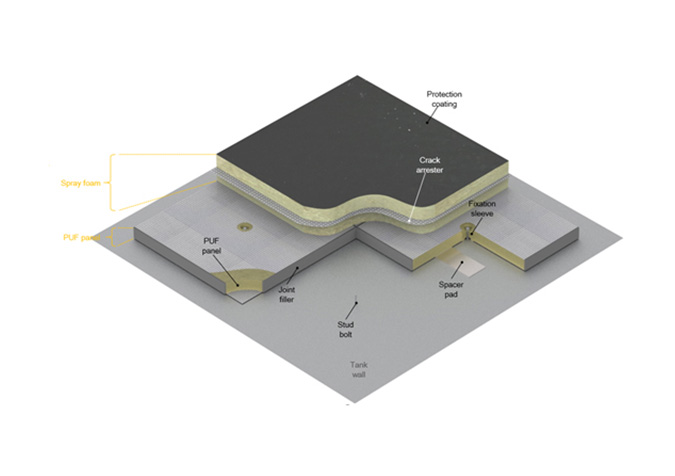

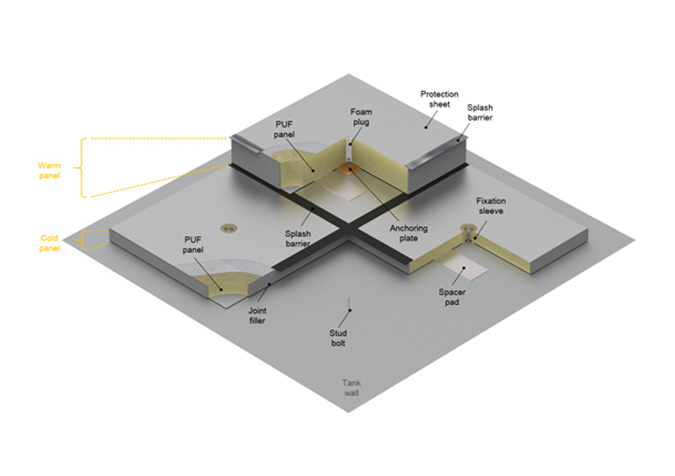

We produce Membrane, the essential material for storing LNG at extremely low temperature

and R-PUF processed insulation (IP) used to maintain LNG in liquefied state.